19 May 2014

18 May 2014

Fidgety Phidgets

This is a bit

technical post, and I make this post, only to record it for benefit of a future

pit builder using the same techniques as I.

While all the ‘Inputs’

in the bit are being handled by either Leo Bodnar’s cards, or by Teensey ++2.00

micro-controller boards. For my purposes, these means have proved to be quite

adequate.

While Arduino boards

could also be used for ‘Output’ purposes, but, long time ago, I chose to go

with Phidget boards.

Alan Dyre had

developed a nifty tool called “FS2Phidgets”, which cleanly interfaces the

Phidget boards with FSX/FSUIPC. It took some learning, but after that this

board/tool is a breeze to use.

Glenn “Tripod” Weston,

has provided a masterpiece of an interface tool called as ‘SuperScript’. This

LUA script interfaces the VRS SuperBug with FSUIPC and provides total control

over all data communication with the airplane.

The SuperScript

provides ‘Memory Offsets’ used by FSUIPC, which could be read/written to, to

interface the state of all cockpit annunciators, with any other driver board.

While programming the “FS

Variable” file for the FS2Phidgets, I came across two idiosyncrasies of the

script, which I thought need to be mentioned.

The SuperScript defines

memory offsets (in HEX) as, for example, “0x66CA”. However, if the same format

is used to declare the offset in FSVariable, it leads to unpredictable results.

I found that if the preceeding “0x” was deleted, (use only 66CA, from above

example), then the offsets worked flawlessly.

The second issue I

faced was in declaring the length of the memory offset. All the output scripts

provided by Tripod are one Byte (8 bits) long, except three which are two byte’s

long (Caution Panel and Left/Right Annunciator Panels). This was done, to

accommodate more than 8 bit assignments in these panel groups.

While declaring

FSVariables in FS2P, if I declared the length of offset as ‘Two’ bytes, then

the results were very unpredictable. It took me all of full day, to finally

figure my way out of this. I realized that FS2P is not able to correctly convert

the HEX to decimal, when using two byte long FS Variables.

Out of the three 2

byte groups that Tripod has provided, the Left/Right Annunciator Panel groups,

actually use only 8 bits, while the rest of the bits are kept for future use.

However, the Caution Panel group uses 10 bits of address space. I split these

two bytes into two single bytes offsets, and accordingly changed bit addresses of the

included parameters.

To illustrate, the

Caution Panel reads the Offset 0x66C0, and, it’s a 16 bit Unsigned Word. The offset

is two bytes long and declares variables from Bit0 till Bit9 (10 bits), while

the remaining six bits are kept free for future use.

I declared the FS2P

FSVariables in Offset 66C0 from Bit0 till Bit7 (8 bits) and then declared the

next memory offset (i.e. 66C1) and declared the Bit8 & Bit9 of the original

offset and Bit0 & Bit1 of the new offset, and voila, everything fit into

place.

I know this is boring,

but, am sure, will help someone someday.

BUNO 22358 is undergoing Taxi Trials

No pictures in today’s

update.

It’s been almost seven

months since, I started the physical fabrication part of the cockpit build. And

it’s four times that time, since I had been researching this subject.

I’m happy to finally

say, that Mk-1, Ver 1.00 of my “VRS Rhino Pit, BUNO 22358, AviaScorp Musings”

is finally up for complete systems integration checks.

The systems

integration checks were planned for the last weekend, but that got consumed

totally in fabricating the HUD gauge. Throughout the week, I was promising

myself, that this weekend, I WILL fire up the pit, and do atleast one test

flight.

I’m happy, that I did.

The pit is not

perfect. Not there, where I want it to be. It’s therefore, I call it a Mk-1, Ver

1.00.

Mk-1 build, when

complete, will have everything I had originally planned. Subsequent Marks, will

incorporate items that I had never planned originally for my pit, for example,

a fully collimated, externally projected HUD, Three overhead projectors instead

of three 23” monitors for the external displays, spanning various components of

the pit on multiple computers instead of a single computer it’s working off,

right now, and maybe, just maybe, if technologies like Occulus Rift mature, I

might consider moving along the VR road also. It’s also planned to make modules

of the pit, quickly replacable, so that I could modify the pit for different

airplanes that I love to fly.

Ver 1.00 of the pit is

just to ‘stop’ further fabrication, at whatever stage I presently am. I realized,

that as I fabricated different parts, my skills also improved. For example, the

HUD that I fabricated last week, was of a much better quality and design,

compared to (let’s say) a UFCP that was fabricated a few months ago, or the pit

tub that was designed and fabricated almost half a year ago. For the past few

months, all I was doing was, breaking the older parts and remaking newer

versions of them. Due to this, while the work continued on a feverish pace, the

pit was never nearing completion.

Future versions of

Mk-1 Pit, will replace the existing components with better built/finished

components. For example, I have realized that some of the annunciator lights

are too dim, or the LEDs are not installed correctly in their enclosures. Or, I’m

also considering fabricating/replacing the SPST/DPST mechanical switches with

electrically or magnetically held/latches switches to more accurately mimic the

actual airplane.

But, all that is for

the future and the coming weeks.

As I type this update,

a small video I have prepared of the state of the pit till today, and as I was

testing it earlier today, is getting uploaded.

That will explain the

current status of the pit much better than all the words out here.

placards and other

switches).

05 May 2014

HUD

During the initial planning stage itself, I had decided that my pit will not have an external HUD, and that I will use the HUD display provided by the VRS model itself.

The only reason for this initial decision, taken more than two years back, was; 'I didn't think it possible for me to be able to build myself a home-built, working, fully collimated HUD'.

A lot has changed in these two years. Thanks to the experiments by folks like Baldrick (on Hornetpit forums), and my own experiments, I now know, I could have built one.

And, I eventually will.

But, in the present design of my cockpit, there is just no more real estate left, to include a working HUD.

It's just about midnight on a Sunday. As per my original plans, I was supposed to complete my pit today. As of Friday, the only thing left for me to do was, design and build an AoA gauge and complete the wiring for all the annunciators.

As I sat down to design the AoA gauge, I decided to build a mock up HUD bracket also. Two day's of weekend, were completely consumed by building this simple device.

Having finished the fabrication part, I have started to layout the wiring harnesses also. Finished it for the 'Caution Panel' and the 'Master Arm Panel'. Tested it out, and it worked like a charm.

Was very happy to see the whole cockpit come alive with all the lights.

Unfortunately, I was too beat to take any pictures.

Will post them, as I complete more of wiring during the week.

The only reason for this initial decision, taken more than two years back, was; 'I didn't think it possible for me to be able to build myself a home-built, working, fully collimated HUD'.

A lot has changed in these two years. Thanks to the experiments by folks like Baldrick (on Hornetpit forums), and my own experiments, I now know, I could have built one.

And, I eventually will.

But, in the present design of my cockpit, there is just no more real estate left, to include a working HUD.

It's just about midnight on a Sunday. As per my original plans, I was supposed to complete my pit today. As of Friday, the only thing left for me to do was, design and build an AoA gauge and complete the wiring for all the annunciators.

As I sat down to design the AoA gauge, I decided to build a mock up HUD bracket also. Two day's of weekend, were completely consumed by building this simple device.

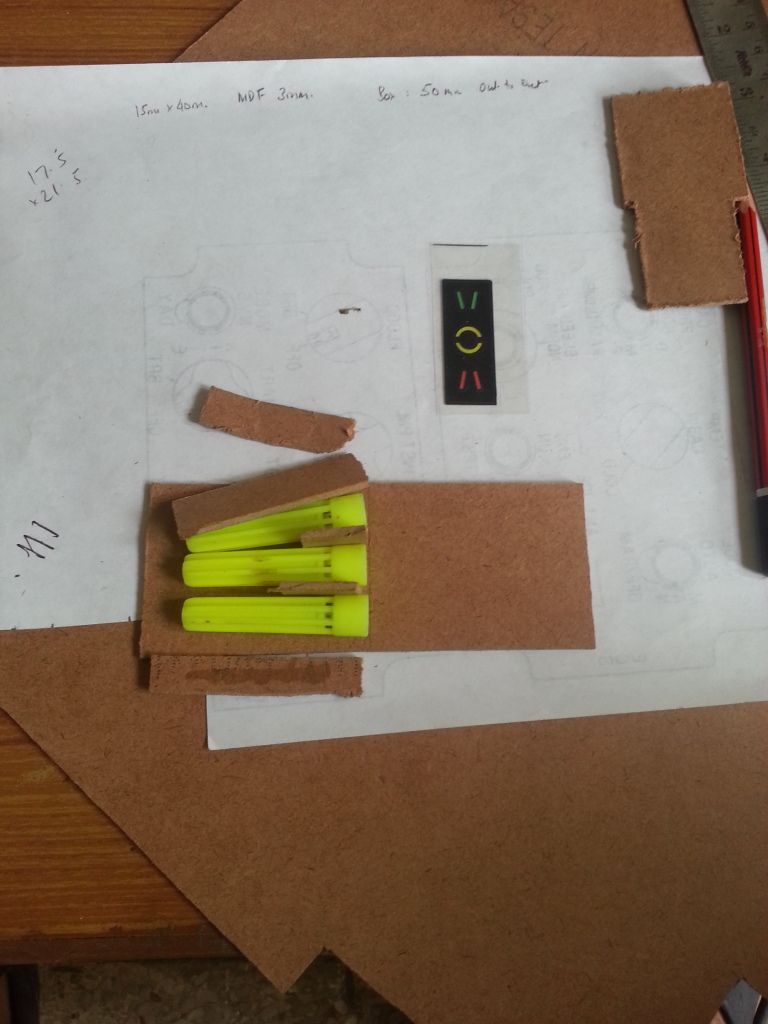

|

| Sizing it all up, with the combiner glass included |

|

| Finalized my decision to go ahead with the use of pen caps. Cut them to the right size, and commenced the build. |

|

| Filing the finished the work piece |

|

| Painted and all ready to be assembled. I felt very satisfied with the overall finish. It took really long to design and build this simple contraption. But, I'm glad I took the time. |

|

| Assembled and all ready to be mounted in the pit The wiring will come next The bottle of play-dough, I mentioned previously, is visible in this picture. |

|

| I was trying to show the curved upper surface the paint finish in this picture, but the picture didn't come out as intended. |

Was very happy to see the whole cockpit come alive with all the lights.

Unfortunately, I was too beat to take any pictures.

Will post them, as I complete more of wiring during the week.

Subscribe to:

Posts (Atom)