The only reason for this initial decision, taken more than two years back, was; 'I didn't think it possible for me to be able to build myself a home-built, working, fully collimated HUD'.

A lot has changed in these two years. Thanks to the experiments by folks like Baldrick (on Hornetpit forums), and my own experiments, I now know, I could have built one.

And, I eventually will.

But, in the present design of my cockpit, there is just no more real estate left, to include a working HUD.

It's just about midnight on a Sunday. As per my original plans, I was supposed to complete my pit today. As of Friday, the only thing left for me to do was, design and build an AoA gauge and complete the wiring for all the annunciators.

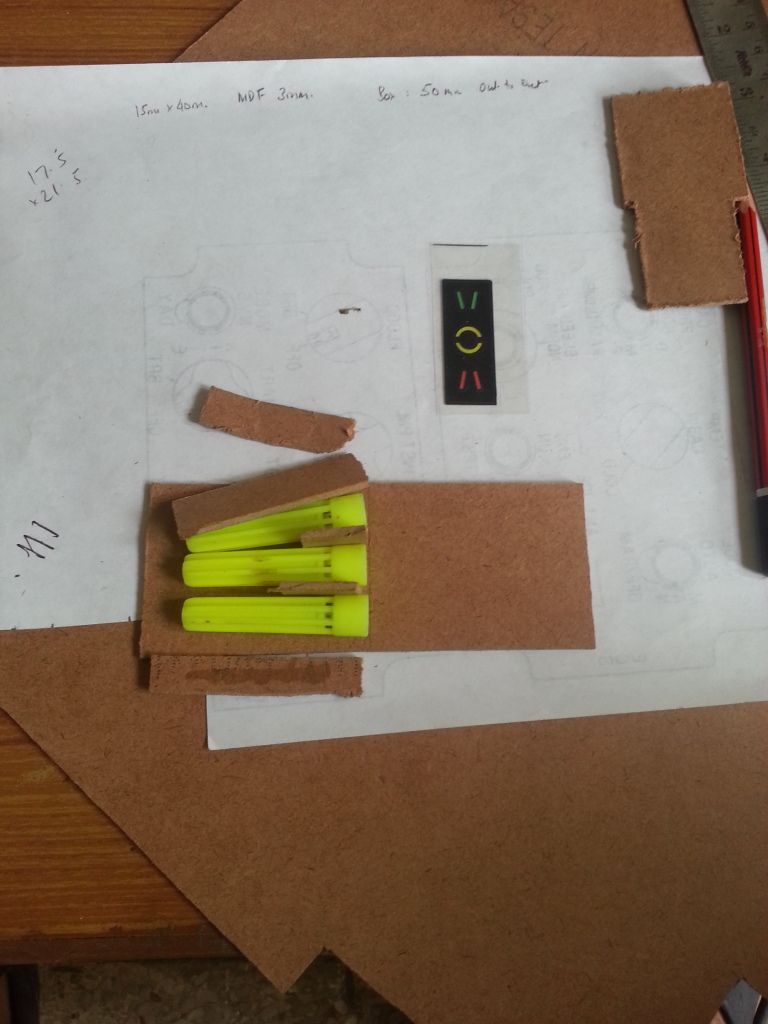

As I sat down to design the AoA gauge, I decided to build a mock up HUD bracket also. Two day's of weekend, were completely consumed by building this simple device.

|

| Sizing it all up, with the combiner glass included |

|

| Finalized my decision to go ahead with the use of pen caps. Cut them to the right size, and commenced the build. |

|

| Filing the finished the work piece |

|

| Painted and all ready to be assembled. I felt very satisfied with the overall finish. It took really long to design and build this simple contraption. But, I'm glad I took the time. |

|

| Assembled and all ready to be mounted in the pit The wiring will come next The bottle of play-dough, I mentioned previously, is visible in this picture. |

|

| I was trying to show the curved upper surface the paint finish in this picture, but the picture didn't come out as intended. |

Was very happy to see the whole cockpit come alive with all the lights.

Unfortunately, I was too beat to take any pictures.

Will post them, as I complete more of wiring during the week.

No comments:

Post a Comment